Oils sludge hails from drilling, exploration, and the procedure of refining different oil resources. It is composed of sludge, water, and oil which can lead to environmental pollution when it is not processed properly. However, oil sludge contains a great deal of oil which creates favorable income opportunities. These are the basic explanations why many investors are purchasing oil sludge pyrolysis plant.

Your Options Available With The Oil Sludge Treatment Plants

-Oil sludge therapy is inclusive of the automated feeding system. It utilizes a direct-condensation technique which assists with assisting to cool gases right into a liquid. Each of the exhaust gas and wastewater is processed within a machine which eliminates environmental pollution.

-The Oil Sludge Recycling plants have an automated warning tool and a pressure gauge which ensures optimal safety during operations.

How Does The Pyrolysis Plant Aid In Treating Oil Sludge

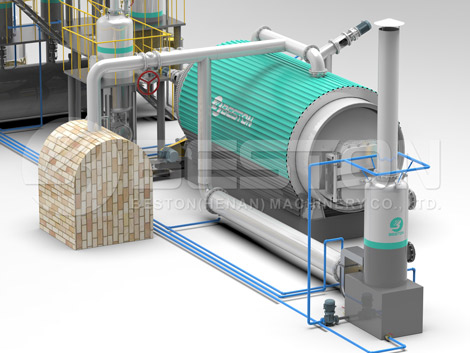

The oil sludge that may be created as being a by-product through the procedure of oil refinery and drilling that is also made up of an assortment of oil and water. The pyrolysis plants for oil sludge assists with separating the sludge and water from the oil which results in an oil product that you can use again. The pyrolysis plants are successful in producing fuel oil of high-quality. The Oil Sludge Pyrolysis plants comprise a hydro-seal, pyrolysis reactor, oil tank, oil condenser, plus a de-casting system. Click here to know more: https://bestonpyrolysisplant.com/.

The Design Of An Oil Sludge Treatment Plant

The key components related to exhaust gas which cannot be liquefied includes alkanes class C1 and C4, which when directly burned poses a substantial danger. The oil sludge pyrolysis machine is created in a way that this gas is first passed by way of a water seal that is included in the first sealed device just before the gas is used by means of fuel. The gas will be sent into the gas burner that is incorporated into another safety device.

-The hydro-seal within these systems serves the goal of stopping the flames from burning back and yes it removes impurities and sulfur which leads to clean desulfurization gas.

-These appliances include a sophisticated pressure and thermometer gauge which performs the function of checking on the pressure and temperature throughout each operation.

-This machine also utilizes a third-generation means of heating which combines exceptional features of indirect and direct heating which guarantees a good operation. See the waste tyre to fuel oil plant here.

The Oil Sludge Pyrolysis Plants come in 3 different types such as the Fully-Automatic Oil Sludge Pyrolysis Plant, Semi-Automatic Oil Sludge Plant, along with the Batch Oil Sludge Treatment Plant. The optimal plant to fit around your needs depends in your budget as well as your allowance. The Oil Sludge Pyrolysis Plants are becoming fashionable as a highly profitable business opportunity. Additionally it is among the finest methods to safely process oil sludge and that is a item that is bad for the planet. Converting oil sludge into a number of useful materials like organic compounds of your low molecular weight together with carbonaceous residue through the entire process of pyrolysis solves the situation of disposal and promotes resource utilization. Visit the site: https://bestonpyrolysisplant.com/waste-tyre-pyrolysis-to-oil/.